Richcoat is now practicing Black Magic

with the addition of the following

BLACK HARDCOAT

MIL –A-8625 Type III Class 2

CLEAR BLACK

MIL –A-8625 Type II Class 2

In addition to:

Hardcoat Anodize AMS 2469, SQM-4P9001A, P3212, PS 6426,

Sulfuric Anodize AMS 2471, ESW- M4P-5A, P3103, PS- 6426 thin, SB 5992

Numerous Aerospace specs. Sulfuric Hard, Clear thin

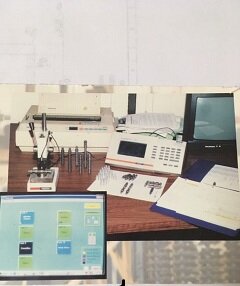

Richcoat Equipment and Capabilities

Why two fully automated anodizing lines? We had to insure ourselves that strict non-human control of the variables must be addressed. The only way we could achieve the above was through automation with computer control of every anodizing variable; chemical, electrical, and mechanical. With our innovative computer system we are able to analyze and maintain the proper chemistry of the electrolyte as well as the cleaner. It monitors the conductivity of all the rinse tanks and corrects them when they are out of assigned parameters. Along with the monitoring and maintaining proper chemistry, all bathes are continually monitored for proper temperatures. This ingenious computer system also regulates the mathematically computed current density of each anodizing cell. Our equipment and computers are designed to handle in excess of 12880 parts per hour and the higher volumes ensure greater control of quality parameters.

PS2000 Anodizing Chemical Management

Chemical Process Control System

The PS2000 program is a computerized control center utilizing graphics and data display to provide a user-friendly interface. The Manager coordinates peripheral actions and maintains an interactive database. It schedules analysis, displays and stores the analytical results received from Analyzer or physical reading from LCU, and uses the information to initiate alerts, alarms, and other automated control functions such as chemical replenishment. It records and organizes important process data for easy retrieval and communicates them to the hosts (Alpha and Omega Lines) serviced by PS2000 System.

The Analyzer is a peripheral used to measure certain chemical concentrations accurately in the process baths. It receives analysis request from the Manager and communicates the results back to the Manager.

The Replenisher receives chemical addition or withdrawal instructions from the Manager based on either programmed conditions or manually entered commands. The system is designed to maintain inventories of chemical feedstocks, coordinate and conduct accurate delivery of the feedstocks, report delivery progress, and report chemical consumption.

The LCU is another Manager peripheral responsible for all other process control functions. IT monitors physical process parameters such as temperature, level, conductivity, pH, voltage, etc. The LCU is designed to receive digital or analog signals from local control devices and relay the information to the Manager.